Castor Wheels / Caster Wheels

We are Dealer, Trader, Specialist, Supplier, Importer, Wholesale, Stockist of Castor Wheels, Hospital Bed Castor Wheels, Heavy Duty Ball Transfer Units, Steel / Mild Steel (MS) / Stainless Steel (SS) / Ball Transfer Units (BTU), Cast Iron Heavy Duty Caster Wheels, CI (Cast Iron) Trolley Wheels, ESD Caster Wheels (Electrostatic Discharge Caster Wheels), Conductive / Dissipative ESD Caster Wheels, Anti Static/ Electric Conductive Polyurethane Wheels, ESD Rubber / Polyurethane (PU) Caster Wheels, Heavy Duty Caster Wheels, Ball Bearings / Roller Bearings, Cast Iron / Steel / Polymer / Polyester / Polyurethane (PU) Heavy Duty Caster Wheels, Ball / Roller / Rolling / Caster Bearings, Leveling Caster Wheels (Leveling wheel / Foot Level Caster), Medical Caster Wheels / Casters, Medical Bed Casters, Polyurethane / Rubber / Plastic / SS (Stainless Steel) / Mild Steel (MS) / Cast Iron (CI) Medical Casters wheels, Conductive / Anti Static Medical Casters Wheels, Nylon Caster Wheels (Nylon Wheels), Heavy Duty Nylon Casters, Round Nylon Caster Wheels, PP (Polypropylene) Caster Wheels, Caster Polypropylene Wheels, Pulley Caster Wheels (Pulley Wheels / Casters), Sheave Rope Pulleys, Sheave Wheels / Casters, Gate Rollers, Heavy Duty Rubber Wheels (Rubber Caster Wheels), Swivel / Rigid Wheels, Soft Rubber / Hard Rubber / Thermoplastic Rubber Wheels, Solid Rubber Wheels, Rubber / Tracked Wheels, Trolleys, Industrial / Heavy Duty / Pallet / Steel / Aluminium Trolleys, Cage Platform / Cylinder / Gas Cylinder / Drum / Fiber Platform / Stain Less (SS) Platform / Manual / Electric Pallet Trolleys, Electric / Manual / Hand / Semi Electric / Forklifts / lifts Stacker, Twin Caster wheels, Polyurethane / Rubber / Nylon / Metal Twin (Dual) Caster wheels, Dual Wheel Casters and Our setup situated at Pune, Maharashtra, India.

Ball Transfer Units (BTU)

A Ball Transfer Units is a type of mechanical device used for conveying or transferring heavy loads or objects with minimal effort. It consists of a large number of small balls, usually made of steel or other durable materials, arranged in a circular pattern within a housing or frame. These balls are designed to roll freely in any direction, allowing for easy movement of objects in all directions.

Ball Transfer Units are commonly used in material handling and conveyor systems, where they provide a smooth and low-friction surface for moving heavy objects, such as pallets, boxes, or machinery, with minimal manual effort. They are typically installed in a recessed or surface-mounted housing or frame, and can be used in various orientations, such as horizontal, vertical, or angled, depending on the specific application requirements.

Cast Iron (CI) Caster Wheels

Cast Iron Caster (Castor) Wheels are a type of wheel used in material handling and transportation applications. They are made of cast iron, which is a durable and heavy-duty material known for its strength and wear resistance. Cast iron caster wheels are typically used in applications where heavy loads need to be transported or moved, and where durability and load-bearing capacity are important. Some common applications of cast iron caster wheels include:

1) Industrial Equipment and Machinery: Cast iron caster wheels are often used in industrial equipment and machinery, such as heavy-duty carts, racks, and platforms. They can handle heavy loads and provide stability and smooth movement in rugged environments.

2) Material Handling and Transport: Cast iron caster wheels are commonly used in material handling and transportation applications, such as dollies, carts, and trucks used in warehouses, factories, and distribution centers. They can withstand heavy loads and provide easy maneuverability for transporting goods and materials.

3) Automotive and Transportation: Cast iron caster wheels are also used in automotive and transportation applications, such as tow dollies, trailers, and utility carts. They can provide reliable and stable movement for towing or transporting heavy loads.

Cast iron caster wheels come in various sizes, load capacities, and configurations, allowing for customization to suit specific application requirements. They are typically designed with a swivel or rigid configuration, with swivel casters allowing for easy maneuverability and change of direction, while rigid casters provide stability and straight-line movement.

ESD Caster (Castor) Wheels (Electrostatic Discharge Caster Wheels)

ESD Caster Wheels are a type of specialized caster wheel designed to prevent the buildup and discharge of static electricity, which can damage sensitive electronic equipment, create safety hazards, and disrupt production processes in certain environments.ESD caster wheels are commonly used in applications where static electricity needs to be controlled, such as in clean rooms, manufacturing facilities, laboratories, electronics assembly lines, and other environments where sensitive electronics or flammable materials are present. ESD Caster Wheels typically have special features and properties that make them suitable for preventing electrostatic discharge.

Some common characteristics of ESD Caster Wheels include:

1) Conductive or dissipative properties: ESD caster wheels are made from materials that are either conductive or dissipative, which allow them to safely conduct or dissipate static electricity, preventing the buildup of static charges on the wheels.

2) Low resistance to ground: ESD caster wheels have low resistance to ground, which helps to quickly and safely discharge any static charges that may accumulate during movement.

3) Non-marking and abrasion-resistant: ESD caster wheels are often made from non-marking materials, such as rubber or polyurethane, to prevent marking or damage to delicate flooring surfaces. They are also typically abrasion-resistant to ensure durability and long-lasting performance.

Heavy Duty Caster (Castor) Wheels

Heavy-Duty Caster Wheels are caster wheels designed to carry and support heavy loads in various applications where mobility and maneuverability are required. Caster wheels are typically attached to the bottom of carts, equipment, or furniture to allow them to roll and swivel for easy movement. Heavy-duty caster wheels are specifically designed to handle heavy loads, often ranging from hundreds to thousands of pounds, and provide reliable performance in demanding environments.

Some common features of heavy-duty caster wheels include:

1) High load capacity: Heavy-duty caster wheels are designed to handle heavy loads, often ranging from hundreds to thousands of pounds, depending on the caster size and material.

2) Durable materials: Heavy-duty caster wheels are typically made from durable materials, such as cast iron, steel, or high-strength polymers, that are resistant to wear, impact, and harsh environments, ensuring long-lasting performance and reliability.

3) Large wheel diameter: Heavy-duty caster wheels often have a large wheel diameter to distribute the load over a larger area, reducing the pressure on the floor and providing stability during movement.

Ball bearings or roller bearings: Heavy-duty caster wheels may be equipped with ball bearings or roller bearings to reduce friction and make movement smoother and more efficient, especially for larger loads.

Heavy-duty caster wheels are commonly used in various applications, such as material handling equipment, carts, dollies, trailers, conveyors, industrial equipment, and other heavy-load applications. When selecting heavy-duty caster wheels, it's important to consider factors such as load capacity, wheel material, wheel diameter, bearing type, brake options, and mounting options to ensure optimal performance and durability for your specific application. It's recommended to consult with a knowledgeable supplier or engineer to select the right heavy-duty caster wheels for your specific needs. Proper installation, usage, and maintenance of heavy-duty caster wheels are also important to ensure safe and efficient material handling operations.

Leveling Caster (Castor) Wheels (Leveling wheels / Foot Level Casters)

A Leveling Casters, also known as a Leveling Wheels Or A Leveling Foot With Casters, is a type of caster wheel that is designed to provide both mobility and Leveling capability. It combines the functions of a caster wheel, which allows for easy movement and maneuverability, with the ability to level and stabilize the equipment or furniture it is attached to.

Leveling casters typically have a swivel caster wheel on the bottom for mobility and maneuverability, and a Leveling foot or pad on the top for Leveling and stabilizing. The Leveling foot or pad can be adjusted in height to compensate for uneven surfaces, allowing the equipment or furniture to be leveled and stabilized for safe and stable operation.

Leveling casters are commonly used in various applications where both mobility and Leveling capability are required, such as industrial equipment, machinery, workbenches, cabinets, furniture, and other applications where stability and precise Leveling are important. When selecting Leveling casters, it's important to consider factors such as load capacity, Leveling capability, wheel material, brake options, and mounting options to ensure optimal performance and durability for your specific application. It's recommended to consult with a knowledgeable supplier or engineer to select the right Leveling casters for your specific needs. Proper installation, usage, and maintenance of Leveling casters are also important to ensure safe and efficient operations.

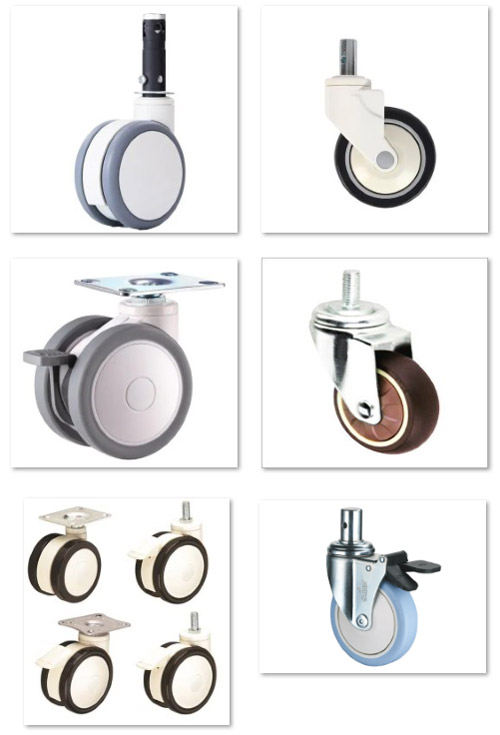

Medical Caster (Castor) Wheels / Casters

Medical Caster Wheels are a type of caster wheels specifically designed for use in health care and medical environments, where cleanliness, maneuverability, and durability are critical. These caster wheels are commonly used in hospital beds, medical carts, medical equipment, and other health care-related applications.

Some key features of medical caster wheels include:

1) Hygienic design: Medical caster wheels are designed to be easy to clean and resistant to corrosion, rust, and chemicals, making them suitable for use in sterile environments. They are often made from materials such as stainless steel, nylon, or medical-grade polymers that are resistant to moisture and can be cleaned easily.

2) Smooth and quiet operation: Medical caster wheels are typically designed to provide smooth and quiet movement, allowing for easy and quiet maneuverability in health care settings without causing disturbances to patients or staff.

3) Load capacity: Medical caster wheels come in various load capacities to accommodate different weight requirements, ranging from light-duty to heavy-duty applications, depending on the specific application and equipment.

4) Mobility and Maneuverability: Medical caster wheels often have swivel capabilities to allow for easy maneuverability and navigation around tight spaces and corners, making them ideal for medical carts and equipment that need to be moved around in a hospital or health care facility.

When selecting medical caster wheels, it's important to consider factors such as hygienic design, load capacity, mobility, brake options, anti-static or conductive properties, and compliance with industry standards to ensure optimal performance and safety in health care settings. It's recommended to consult with a knowledgeable supplier or engineer to select the right medical caster wheels for your specific needs. Proper installation, usage, and maintenance of medical caster wheels are also important to ensure safe and efficient operations in health care environments.

Nylon Caster (Castor) Wheels (Nylon Wheels)

Nylon Caster Wheels are a type of caster wheels that are made from nylon, a type of high-strength polymer known for its durability, strength, and resistance to wear and tear. Nylon caster wheels are commonly used in a wide range of applications due to their excellent performance characteristics.

Some key features of nylon caster wheels include:

1) High load capacity: Nylon caster wheels have a high load capacity, ranging from light-duty to heavy-duty applications, making them suitable for various equipment and furniture.

2) Durability: Nylon is a tough and durable material that is resistant to abrasion, chemicals, moisture, and UV radiation, making nylon caster wheels ideal for demanding environments and long-term use.

3) Smooth and quiet operation: Nylon caster wheels provide smooth and quiet movement, allowing for easy and quiet maneuverability without causing disturbances to the surroundings.

4) Versatility: Nylon caster wheels are versatile and can be used on various surfaces, including concrete, tile, carpet, and hardwood floors, making them suitable for different environments and applications.

Nylon caster wheels are commonly used in a wide range of applications, such as furniture, carts, dollies, racks, conveyors, industrial equipment, and material handling equipment. When selecting nylon caster wheels, it's important to consider factors such as load capacity, durability, smoothness of operation, versatility, corrosion resistance, and cost-effectiveness to ensure optimal performance for your specific application. It's recommended to consult with a knowledgeable supplier or engineer to select the right nylon caster wheels for your needs. Proper installation, usage, and maintenance of nylon caster wheels are also important to ensure safe and efficient operations.

PP (Polypropylene) Caster (Castor) Wheels

PP (Polypropylene) Caster Wheels are a type of caster wheels that are made from polypropylene, a thermoplastic polymer known for its lightweight, durability, and resistance to chemicals, moisture, and impact. PP caster wheels are commonly used in a wide range of applications where lightweight and corrosion resistance are important.

Some key features of PP caster wheels include:

1) Lightweight: PP caster wheels are lightweight, making them easy to maneuver and suitable for applications where weight is a concern, such as in furniture, carts, and other equipment that needs to be moved frequently.

2) Durability: Polypropylene is a durable material that is resistant to chemicals, moisture, and impact, making PP caster wheels suitable for use in demanding environments.

3) Corrosion resistance: PP caster wheels are resistant to corrosion, making them suitable for use in environments where moisture or chemicals may be present, such as in industrial or outdoor applications.

4) Cost-effective: PP caster wheels are generally cost-effective compared to other materials, making them a budget-friendly option for many applications.

PP Caster Wheels are commonly used in a wide range of applications, such as furniture, carts, dollies, racks, conveyor systems, medical equipment, and material handling equipment. When selecting PP caster wheels, it's important to consider factors such as load capacity, durability, smoothness of operation, corrosion resistance, and cost-effectiveness to ensure optimal performance for your specific application. It's recommended to consult with a knowledgeable supplier or engineer to select the right PP caster wheels for your needs. Proper installation, usage, and maintenance of PP caster wheels are also important to ensure safe and efficient operations.

PU (Polyurethane) Caster (Castor) Wheels

PU (Polyurethane) Caster Wheels are a type of caster wheels that are made from polyurethane, a durable and versatile material known for its excellent load capacity, wear resistance, and ability to provide smooth and quiet operation. PU caster wheels are commonly used in a wide range of applications where high performance and floor protection are important.

Some key features of PU caster wheels include:

1) Load capacity: PU caster wheels have a high load capacity, ranging from light-duty to heavy-duty applications, making them suitable for various equipment and furniture.

2) Durability: Polyurethane is a durable material that is resistant to wear and tear, chemicals, and abrasion, making PU caster wheels ideal for demanding environments and long-term use.

3) Smooth and quiet operation: PU caster wheels provide smooth and quiet movement, allowing for easy and quiet maneuverability without causing disturbances to the surroundings. They also provide excellent shock absorption, reducing vibration and noise during operation.

4) Floor protection: PU caster wheels are typically non-marking and do not leave marks or scratches on floors or surfaces, making them suitable for use in environments where floor protection is important, such as in residential or commercial settings.

PU Caster Wheels are commonly used in a wide range of applications, such as furniture, carts, dollies, racks, conveyor systems, medical equipment, and material handling equipment. When selecting PU caster wheels, it's important to consider factors such as load capacity, durability, smoothness of operation, floor protection, chemical resistance, aesthetics, and cost-effectiveness to ensure optimal performance for your specific application. It's recommended to consult with a knowledgeable supplier or engineer to select the right PU caster wheels for your needs. Proper installation, usage, and maintenance of PU caster wheels are also important to ensure safe and efficient operations.

Pulley Caster (Castor) Wheels (Pulley Wheels / Caster)

Pulley Caster:

Pulley Caster Wheels are a type of caster wheel that incorporates a pulley or sheave mechanism to facilitate movement or transfer of a load. The pulley mechanism allows for easy and efficient movement of heavy loads by reducing the force required to move them. Pulley caster wheels consist of a wheel that rotates on an axle and a pulley or sheave mounted on the wheel's circumference. A cable or rope is threaded through the pulley and used to pull or push the load. The load's weight is distributed across the pulley and caster wheel, reducing the force required to move the load.

Gate Rollers:

Gate rollers are devices used to support and guide gates as they slide open and closed. They consist of a wheel mounted on an axle and attached to a bracket or frame that is mounted on the gate. The wheel rotates on the axle as the gate moves, reducing friction and allowing for smooth movement.

Gate rollers are commonly used in various types of gates, such as sliding gates, cantilever gates, and overhead track gates. They are designed to bear the weight of the gate and guide it along a track or rail, ensuring smooth and easy movement.

Rubber Wheels (Rubber Caster Wheels)

Rubber Caster (Castor) Wheels are a type of caster wheel that features a rubber tire or tread on the wheel that comes in contact with the ground or surface. The rubber tire provides excellent shock absorption and noise reduction, making them a popular choice for applications where quiet movement and vibration reduction are important.

Rubber caster wheels are available in various sizes, load capacities, and designs such as swivel or rigid. They can also come in different types of rubber, such as soft rubber, hard rubber, or thermoplastic rubber, depending on the application requirements. It's important to select the right rubber caster wheel for the application to ensure safe and efficient operation.

Proper installation, usage, and maintenance of rubber caster wheels are also important to ensure safe and efficient operation. The wheels should be regularly checked for wear and damage, and cleaned as necessary to ensure optimal performance.

Industrial Trolleys

Industrial Trolleys :

Industrial trolleys are specifically designed for use in industrial environments, such as factories, warehouses, and workshops. They are typically more heavy-duty and durable than other types of trolleys, as they are designed to handle heavier loads and withstand rougher handling..

Industrial trolleys can also come with additional features such as brakes, anti-tip devices, and adjustable shelves. The type of industrial trolley required depends on the specific application and requirements of the user.

Pallet Trolleys (Pallet Jacks / Pallet Trucks) :

A Pallet Trolleys, also known as a Pallet Jacks or Pallet Trucks, is a type of material handling equipment used to lift and move pallets within a warehouse or industrial setting. It consists of a wheeled platform with forks that can be inserted into the openings of a pallet.

Pallet Trolleys are available in two types - manual and electric. Manual pallet trolleys are powered by human labor, while electric pallet trolleys use a battery-powered motor. Electric pallet trolleys are more efficient and easier to use, making them popular in larger facilities, but they also tend to be more expensive.

Stackers:

Stackers are material handling machines that are used to lift and move heavy loads from one location to another. They are similar to forklifts but are more compact and designed for use in smaller spaces.

Stackers come in various types, including manual, semi-electric, and fully electric models. Manual stackers require the operator to manually pump a lever to raise and lower the load, while electric stackers use a motorized system to lift and lower the load. Stackers are typically used in warehouses, factories, and other industrial settings to move materials and goods around. They are ideal for lifting loads to high shelves or storage areas that are out of reach of other equipment.

Gas Cylinder and Drum Trolleys

A Cylinder and Drum trolleys, also known as a Gas Cylinder and Drum Trolleys, is a type of material handling equipment used to transport gas Cylinder and Drum in a safe and efficient manner. Cylinder and Drum trolleys are commonly used in industrial, commercial, and medical settings.

Cylinder and Drum trolleys come in various sizes and configurations, depending on the size and type of gas Cylinder and Drum s they are designed to transport. They are typically made of steel or aluminium and feature wheels and handles for ease of movement.

Some Cylinder and Drum trolleys have a single platform that can hold one Cylinder and Drum, while others have multiple platforms to hold several Cylinder and Drum s at once. Cylinder and Drum trolleys may also feature safety chains or straps to secure the Cylinder and Drum s during transport.

Twin Caster (Castor) Wheels

Twin Caster Wheels, also known as Dual Wheel Casters, are a type of caster that features two wheels attached to a single mounting plate. The twin wheels are typically positioned side by side and rotate independently of each other.

Twin caster wheels are designed to distribute weight evenly over a larger surface area, providing increased stability and load capacity compared to single-wheel casters. They are commonly used in heavy-duty applications, such as industrial machinery, carts, and equipment racks.

Twin Caster Wheels are available in various sizes and configurations, with different wheel materials, sizes, and load capacities to suit different applications. They can be made of materials such as polyurethane, rubber, nylon, or metal.

Some twin caster wheels have a locking mechanism that can be engaged to prevent the wheels from moving, providing additional stability when needed. Twin caster wheels may also have swivel or rigid mounting options, allowing them to be used for both directional and fixed applications.